| Khoom siv | 100% nkauj xwb Mitsubishi khoom |

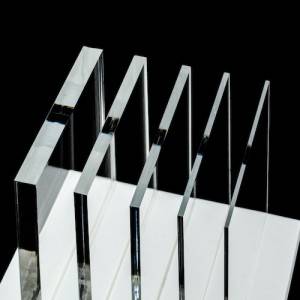

| Thickness | 1.8, 2, 3, 4, 5, 8, 10, 15, 20, 30, 50,60mm (1.8-60mm) |

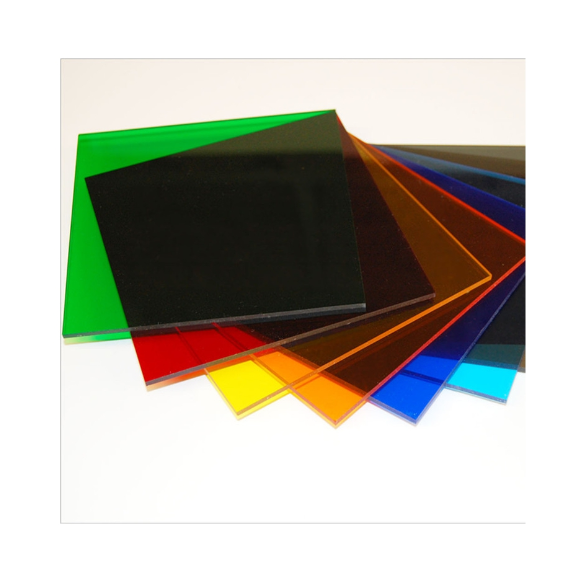

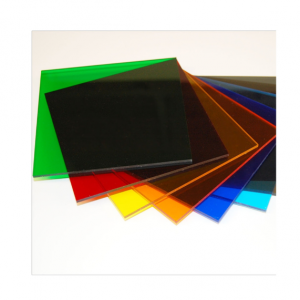

| Xim | pob tshab, dawb, opal, dub, liab, ntsuab, xiav, daj, thiab lwm yam OEM xim OK |

| Txheem loj | 1220 * 1830, 1220 * 2440, 1270 * 2490, 1610 * 2550, 1440 * 2940, 1850 * 2450, 1050 * 2050, 1350 * 2000, 2050 * 3050, 1220 * 3050 hli |

| Daim ntawv pov thawj | CE, SGS, DE, thiab ISO 9001 |

| Khoom siv | Imported iav qauv (los ntawm Pilkington iav hauv UK) |

| MOQ | 2 tons, tuaj yeem sib xyaw nrog cov xim / qhov ntau thiab tsawg / tuab |

| Kev xa khoom | 10-25 hnub |

| Peb qhov ntau thiab tsawg | ||||||||

| Nrog ntug (mm) | 1250 × 1850 hli | 1250 × 2450 hli | 1050 × 2050 | 1850 × 2450 hli | 2090 × 3090 hli | 1550 × 3050 hli | ||

| Tsis muaj ntug (mm) | 1220 × 1830 hli | 1220 × 2440 hli | 1020 × 2020 | 1820 × 2420 hli | 2050 × 3050 hli | 1500 × 3000 hli | ||

| Nco tseg: Tag nrho peb muaj txog li 30 qhov sib txawv, tiv tauj peb kom paub meej ntxiv. | ||||||||

| Thickness:1.5-30 hli | ||||||||

| Lub cev khoom ntawm Cast Acrylic Sheet | ||||||||

| QHOV TSEEB | UNIT | VALUE | ||||||

| MECHANICAL | Specific Gravity | — | 1.19-1.2 Nws | |||||

| Roswell Hardness | kg/cm 2 | M-100 | ||||||

| Shear Strength | kg/cm 2 | 630 | ||||||

| Flexural zog | kg/cm 2 | 1050 | ||||||

| Tensile zog | kg/cm 2 | 760 ib | ||||||

| Compressive zog | kg/cm 2 | 1260 | ||||||

| Hluav taws xob | Didlectic zog | Kv/mm | 20 | |||||

| Nto Resistivity | Ohm | > 1016 | ||||||

| OPTICAL | Lub teeb Transmittance | % | 93 | |||||

| Refractive Index | — | |||||||

| THERMAL | Tshwj xeeb kub | Cal/g ℃ | 0.35 Nws | |||||

| Coefficient ntawm Thermal Cortductivily | Cal/xee/cm/℃/cm | |||||||

| Kub txoj kev Temp | ℃ | 140-180 : kuv | ||||||

| Kub Defomation Temp | ℃ | 100 | ||||||

| Thermal Expansion Coefficient | Cmfcm/V | 6 × 10-5 | ||||||

| MISCELLANEOUS | Kev nqus dej (24 teev) | % | 0.3 | |||||

| Teste | % | Tsis muaj | ||||||

| tsw | ||||||||